Do you want to know What is Industry 4.0? Everything you need to know about Industry 4.0.

It's a smart factory but before Industry 4.0 there was steam at the beginning and the first machines that mechanized part of the work of our ancestors. The next was electricity, the assembly line and the birth of mass production.

The third era of industry came with the advent of computers and the principles of automation. Then robots and machines were able to replace human workers who were on a production line.

And now the industrial revolution called Industry 4.0 begins, in which computers and automation come together in a whole new way.

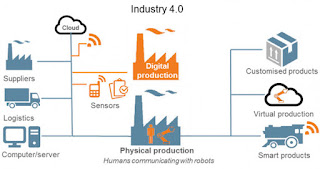

Remote robotics are connected to control systems that are equipped with machine learning algorithms, which can learn and control robotics with very little input from human operators.

Industry 4.0 introduces the "smart factory", where cyber-physical systems monitor the physical processes of a factory and make decentralized decisions.

The physical systems are called the Industrial Internet of Things. They communicate and work with each other and with people, in real-time via the wireless web.

When are you Industry 4.0?

Before a factory or system can be called Industry 4.0, it must contain at least the following:

Interoperability: machines, devices, sensors, and people connected and communicating

Information transparency: the systems create a virtual copy of the physical world through sensor data so that they can place information in the right context

Technical assistance: both the ability of the system to support people in decision making and problem-solving and the ability to help people with tasks that are too difficult or unsafe for people

Decentralized decision making: the ability of cyber-physical systems to make simple decisions themselves and become as autonomous as possible

What are the challenges at Industrie 4.0?

As with any major shift, there are challenges inherent in applying an industry 4.0 model, such as:

☛Data security issues are considerably increased by integrating new systems and more access to such systems.

Also, this makes its product knowledge an IT security problem.

☛A high degree of reliability and stability are required for successful cyber-physical communication, which can be difficult to reach and maintain.

☛Maintaining the integrity of the production process with less human supervision can become a barrier.

☛The loss of highly paid human jobs is always a concern when new automation is introduced.

☛And avoiding technical problems that can cause expensive production outages is always a concern.

Moreover, there is a systematic lack of experience and manpower to create and implement these systems - not to mention the general reluctance of stakeholders and investors to invest heavily in new technologies.

Advantages of an Industry 4.0 model

The advantages of an industry 4.0 model can outweigh the disadvantages for many production companies. In very dangerous work environments, the health and safety of human workers can be drastically improved.

Supply chains can be controlled more easily when data is available at every level of the production and delivery process.

Computer controllers could provide much more reliable and consistent productivity and output. The results for many companies could then be increased sales, profit and market share.

Conclusion

Reports have even suggested that emerging markets such as India can benefit enormously from the Industry 4.0 model.

The American city of Cincinnati, Ohio has even proclaimed itself "Industry 4.0 demonstration city" to stimulate investment and innovation in the manufacturing sector there.

So the question is not whether Industry 4.0 is coming, but how fast! As with Big Data and other business trends, we suspect that early adopters will be rewarded for their courage to jump into this new technology.

And for those who avoid changes, there is a risk of being irrelevant and being left for dead.

The Industrial Internet of Things: It is here, It works, It is Ignition

Ignition IoT by Inductive Automation is an end-to-end Industrial Internet of Things ( IIdD ) solution that combines the fantastic efficiency of the MQTT data transfer protocol with unlimited data collection and development power of the industrial application platform Ignition.

In essence, industry 4.0 is the trend towards automation and data exchange in manufacturing technologies and processes which include cyber-physical systems (CPS), the internet of things (IoT), industrial internet of things (IIOT), cloud computing, cognitive computing and artificial intelligence.

Post new comment

Please Register or Login to post new comment.